Technology

Creating the future with trust

Swiss-Type Millturn Compound Lathe

OEM/ODM

Sample Making

Batch Production

The outstanding advantages are mainly manifested in the following aspects.

(1) Shorten the product manufacturing process chain and improve production efficiency.

Turning and milling can complete all or most of the processing procedures in one project, thereby greatly shortening the product manufacturing process chain. In this way, on the one hand, the production auxiliary time caused by the change of the loading card is reduced, and at the same time, the manufacturing cycle and waiting time of the tooling and fixture are also reduced, which can significantly improve the production efficiency.

(2) Reduce the number of clamping and improve the machining accuracy.

The reduction in the number of card loadings avoids the accumulation of errors due to positioning fiducial conversions. At the same time, the precision control of the manufacturing process can be realized, thereby improving the processing precision of the product.

(3) Reduce the floor space and reduce the production cost.

Although the price of a single turn-milling compound processing equipment is relatively high, due to the shortening of the manufacturing process chain and the reduction of equipment required for the product, as well as the reduction of the number of fixtures, workshop area and equipment maintenance costs, it can effectively reduce the overall fixed assets. The cost of investment, production operation and management.

Turning and milling machine features:

- Using high-precision built-in spindle

- Free-moving operation improves work efficiency

- Mass production of various small and complex parts

- Slender and complex processes can be processed and formed at one time

- Provide high-speed processing, diversified processing

- Configurable automatic feeding device to improve efficiency

Processing Capacity

Length Range

Total length:L 0.5~600mm

Tolerance:L ± 0.01mm

Outer Diameter Range

Tolerance:Φ ± 0.005mm

Material Shape

Round bar

Seamless hollow round bar

Square bar

Hexagonal bar

Processing Material

Steel

1144, 1215, 12L14, 1015, S15C, S45C, SUJ2, SKD11, SCM415, SCM435, SNCM439, SCM440, SNCM220 etc.

Stainless steel

SUS303, SUS304, SUS316, SUS416, SUS410, SUS420, SUS630 etc.

Aluminum

2011, 2024, 5052, 6061, 6066, 6082, 7075 etc.

Copper

Red copper-C1100, Phosphor bronze-C5191, Brass-C3604, Lead-free copper-C6802, Aluminum bronze, Environmentally friendly copper etc.

Industrial Plastics

POM, DELRIN, PTEE, PVC etc.

※If you need sizes and materials other than the above, please feel free to contact us. ZTIND will reply you as soon as possible.

OEM Product Category

Medical Device Parts

Medical equipment parts processing

Precision electronic parts processing

Communication parts processing

Automotive parts processing

Power tool parts processing

Construction machinery parts processing

Agricultural machinery parts processing

Energy equipment parts processing

Measuring & Inspection Equipment

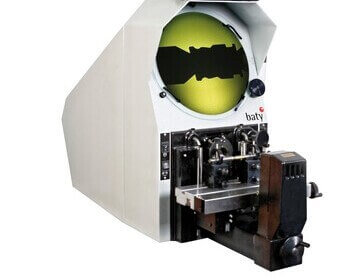

UK Baty Optical Projector

BATY horizontal projector has a high-definition 340mm projection screen and a 175X100mm measuring table.

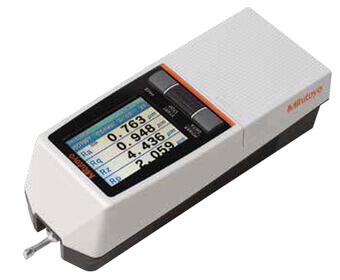

Japan Mitutoyo Surface Roughness Tester

It can measure various postures such as side wall, upward, downward, and oblique angle. It can adjust various postures and position measurement of complex workpieces through accessories such as altimeter adapters and special measuring benches, which can further improve the measurement accuracy.

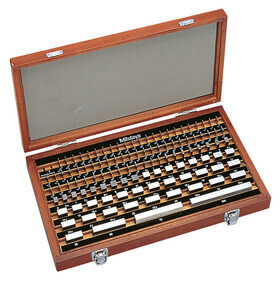

Japan Mitutoyo Block Gauge

A block gauge is a standard tool for precision measurement and can be used as a standard part for length measurement.

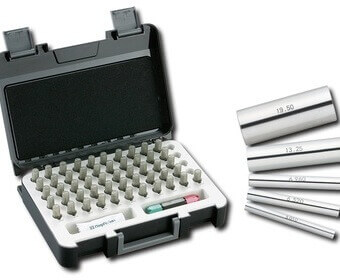

Japan Niigata Seiki Pin Gauge

It is used in the measurement of hole diameter, hole distance and internal thread in mechanical and electronic processing, especially suitable for the measurement of bending groove width and mold size. It can also be used as a stop gauge and the depth of workpiece holes.

Image Measuring Instrument

It can quickly detect the contour, surface size, angle and position of various complex and precision parts, especially the micro-detection and quality control of precision parts, and can be used in product development, and other fields.

Japan, Germany, Switzerland-made inspection measuring tools & Inspection tool

Gauge & Checking Tool Included

Height gauge, depth gauge, vernier caliper, micrometer, screw ring gauge, screw thread gauge, etc.

Assist in Post-Processing

Handling and Management

From raw material to actual finished product shipment, products often have different processing processes. If there is a lack of complete support and management in the process, it often costs huge manpower and time.

Machining

Drilling, Punching,

Tooth rolling, Gear hobbing, Embossing

EDM, Wire EDM,

All kinds of grinding

(centerless, double-sided, inner hole)

Heat Treatment

Normalization

Annealing

Carburization

Induction hardening

Nitrocarburizing

Surface Treatment

Multicolored zinc plated

Nickel-plated zinc alloy

Electroless nickel plating

Zinc Phosphate/Meng Coat Film Treatment

Nickel plated copper

Anode/hard film anode

Passivation of stainless steel

Dyed black

Sandblasting

Laser engraving

Other Process

NYLOK treatment of screws